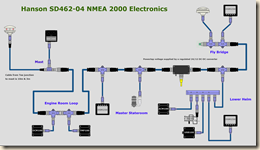

The largest project on the boat this winter has been to take advantage of the NMEA2000 backbone running through our boat and increase the level of system monitoring that we do.

When Seahorse Marine built our boat a couple of years ago, we had them install many components that operated using the marine industry standard NMEA2000. The big advantage of this system is that data and power for the components all run in one backbone cable. When you want to add a module you insert “T” junction that taps into the backbone and pulls data and power off on to a drop line to the new module. So long as you comply with some relatively straightforward restrictions on cable lengths it is pretty idiot proof. Once a module is on the backbone and some minor configuration completed, its data is available in the display modules elsewhere in the boat.

The DC module (DCM100) measures voltage, current and temperature. I installed the voltage and current sensors to measure the output from the DC charging system (either the alternator or the inverter/charger). The temperature being measured is the house bank battery.

The AC module (ACM100) measures voltage and current. I installed its sensors at the output from the AC source selector switch. There are analog meters at the electrical panel that do the same thing but 1) I have to make the effort to look at them and 2) the sensitivity of the meters is pretty coarse.

I installed a probe on the engine start battery alternator but did not attach it to the TMP100 since I ran out of inputs. Depending on what temperatures I think are important to monitor, I could add it to the mix by swapping something else out.

Now that I can gather all of this additional data, I’ll have to give it some time while I build up a baseline to know when things are operating normally and when something is not right as reflected by values (e.g., temperatures) outside the norm.